Cost and Environmental Benefit

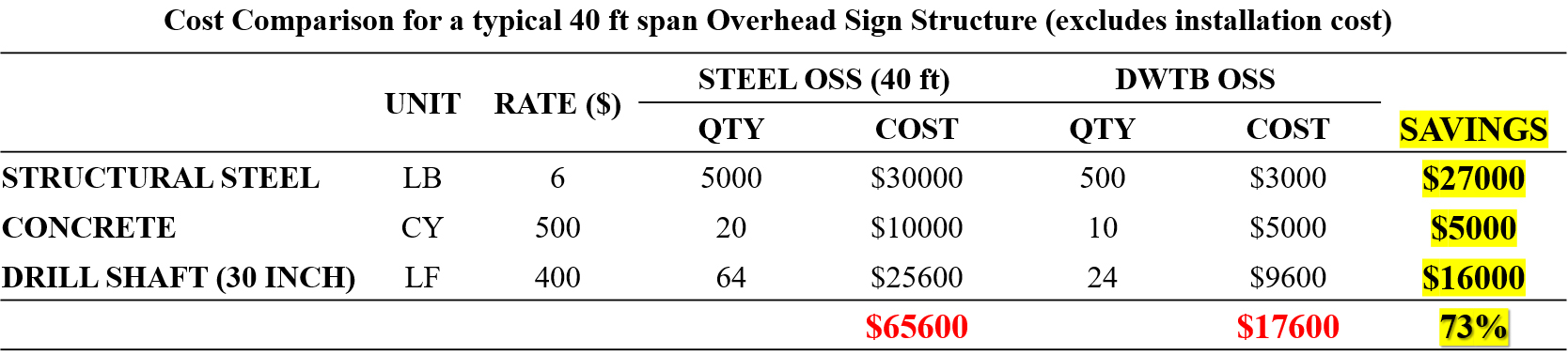

- For a typical 40-foot span OSS, the use of repurposed DWTB leads to a remarkable reduction in raw material costs, achieving approximately 73% savings.

- This significant cost reduction translates into a saving of 4,500 pounds of steel and 10 cubic yards of concrete per structure.

- Such material savings are crucial for reducing overall construction costs, minimizing the reliance on new raw materials.

- A typical 40-foot span OSS, results in an estimated reduction of CO2 emissions by 242 tons per OSS structure compared to conventional recycling methods.

- The reduction is attributed to the lower energy requirements for reprocessing the DWTB for OSS, steel manufacturing and fabrication, and concrete production.

- This approach provides an EoL solution and extends the life of blades by another 50 years (approx.) as a second life application.

* Blade cost is Zero (in fact negative)

* Steel OSS cost increases exponentially with increase in span